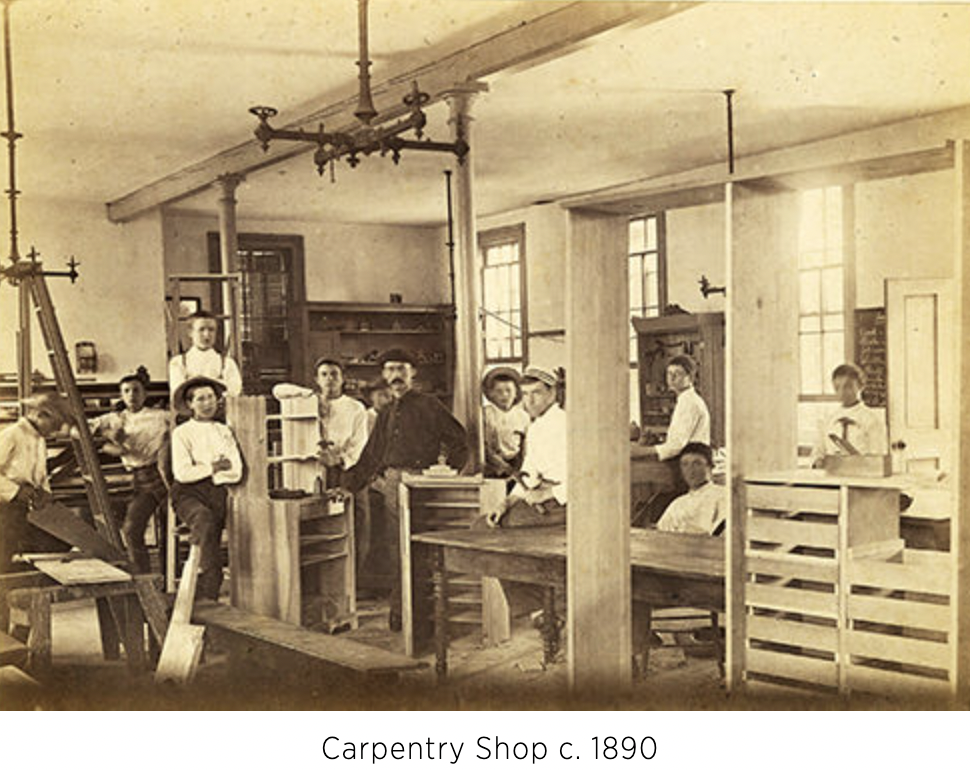

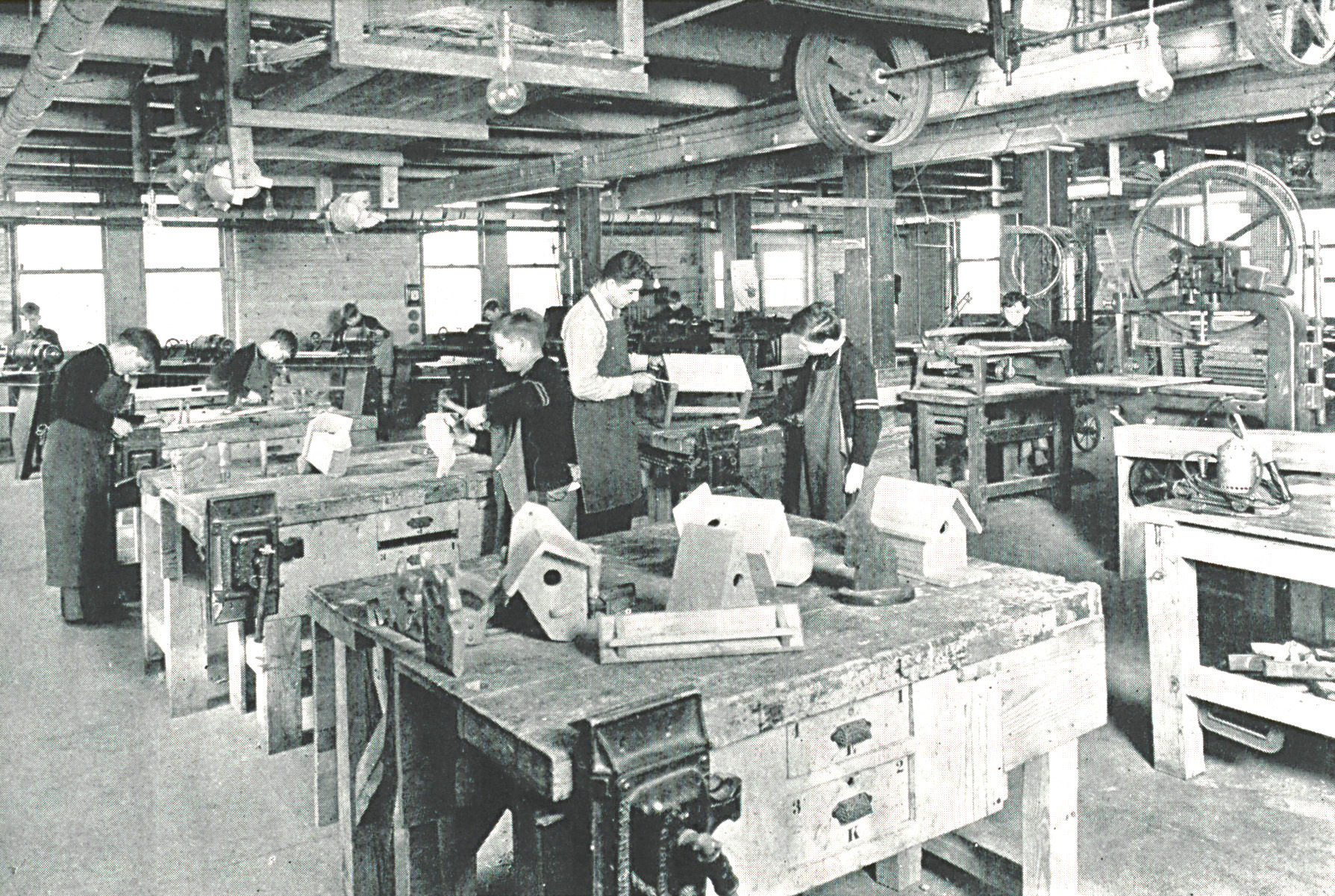

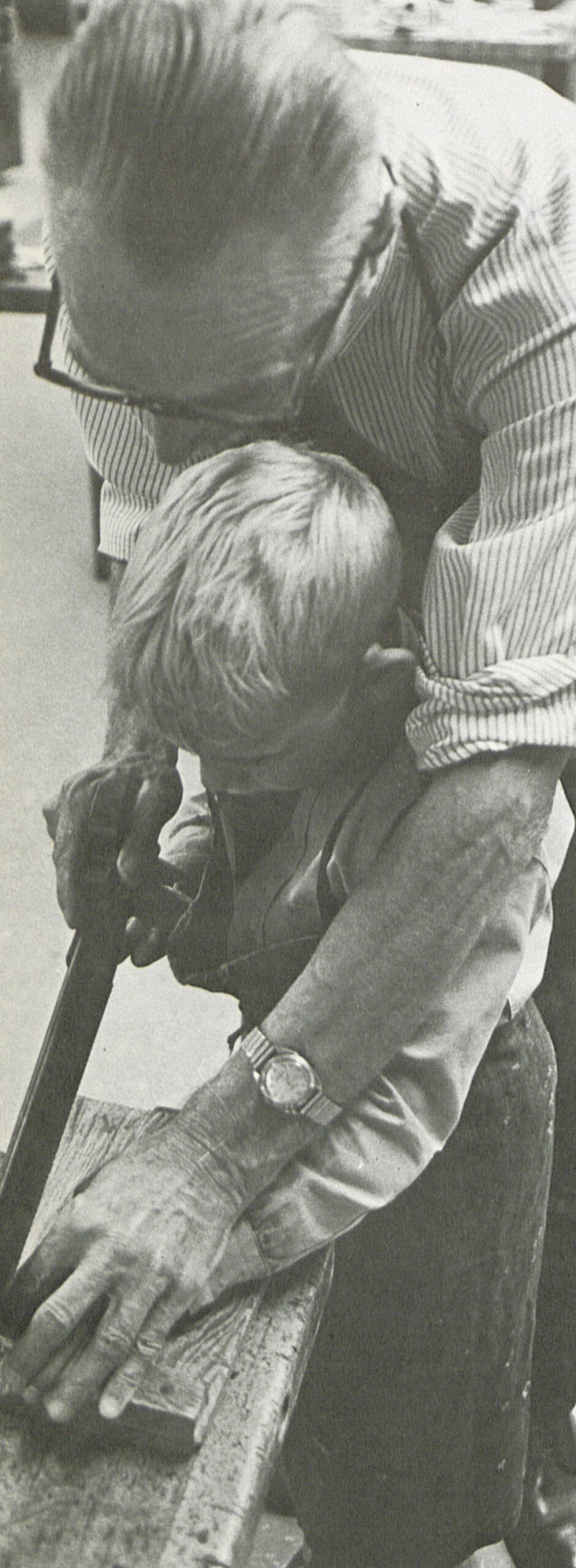

Along with classroom learning, McDonogh had an extensive shop program, and students who completed the program often qualified as skilled artisans in many types of jobs. The vocational program also provided practical background for those who planned to study engineering in college. In addition to craftsmanship, through hands-on learning, boys in the early 1950s practiced “modern industrial production.” For example, in woodshop, after calculating the necessary materials and planning the work in progressive steps, they produced new doors for the School’s book cabinets in an assembly line, as it would have been done in a factory.

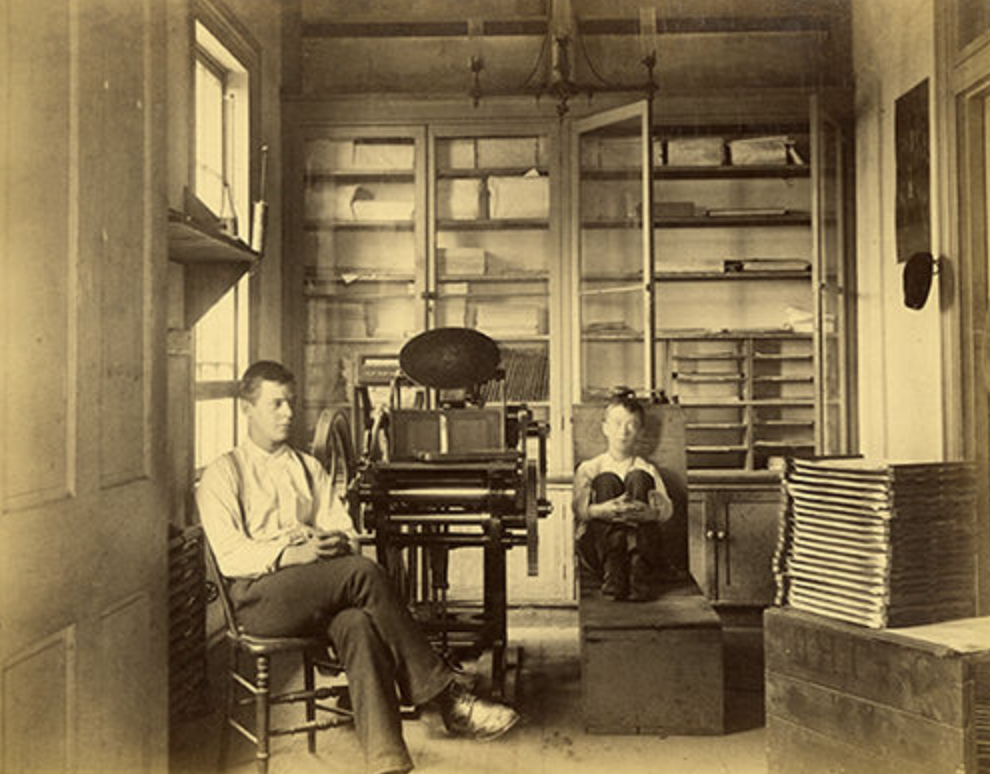

Students also learned the basics of auto maintenance by working on second-hand cars and even built a workable farm tractor from old automobile parts salvaged from junkyards. Other practical skills included typing, shorthand, and the preparation of business letters.

Today, students can directly experience the fundamentals of physics, math, and chemistry in the Fader Innovation Center (see story No. 14 Innovation Happens Here), home to McDonogh’s robotics and engineering programs as well as in the Rao Innovation Center located in the Greenebaum Middle School. Here, students learn to use bandsaws, table saws, chop saws, grinders, sanders, and lathes to build their projects in the more traditional cut room. They also learn digital fabrication with an 800-pound laser cutter, 3D printers, a heat press, and an embroidery machine.